AQUAmax is not the latest cartoon super hero. It is corn genetics that have been developed to perform better in the presence of drought stress. Drought is a relative term. I have customers that demand drought stress tolerance because they farm land where yields will drop from 175 bu to 140 bu under drought stress. I sometimes remind them that there are soils in the province that will yield 110 bu under drought stress, so they should feel fortunate. Regardless, drought is a serious problem which can take 50-60 bu away from a grower. There is not a worse feeling than watching your crop whither in the summer after you have done your best to give it a good start by planting it right, fertilizing it properly and eliminating weeds.

Pioneer has reached back in the gene bank, (read my previous post "Echos of Henry Wallace"), selected DNA that is linked to drought tolerance and incorporated this old DNA into newer genetics. The result is a unique line that delivers superior yield in both water stressed and non water stressed environments.

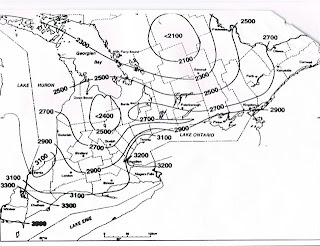

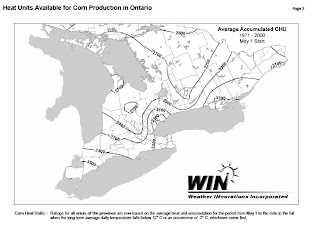

There are two hybrids being tested this year in Ontario. P0210HR is a 3100 heat unit, double stack hybrid and P0791HR is a 3250 heat unit, double stack hybrid. Very cool and very much worthy of super hero status.Optimum™ ACREmax™

Pioneer is introducing Optimum™ Intrasect™ insect protection this year which is the basis for Optimum ACREmax. I admit to being a lousy marketer. I would fall asleep at the table debating names like Optimum AQUAmax, Optimum ACREmax, Optimus PRIME. Whatever, as long as it works.

Optimum Intrasect hybrids combine Herculex I Bt technology with YieldGard Bt technology. These hybrids contain 2 modes of action for European Corn Borer which allow the refuge requirement to drop from 20% to 5%.

The difference with Optimum ACREmax is the 5% refuge is blended with the Intrasect hybrid in the same bag making refuge compliance simple. This concept is still pending regulatory approval.

We will be testing two platforms this year, 38N82 (2700 heat unit - 38N85 family) and 35F33 (3100 heat unit - 35F37 family). These two hybrids will control Western Bean Cutworm as well.

Morris is right. This is exciting.